From 'Mess' to Clarity: AI Precisely Analyzes Tumor Cell Diversity to Aid Personalized Combination Therapies}

AI-driven analysis reveals five new tumor cell types, transforming understanding of tumor heterogeneity and enabling targeted, personalized cancer treatments with significantly improved accuracy.

Video: A complete run of AMASE, taking 8 hours and 22 minutes, including 66 XRD measurements at 11 temperature points. (Source: Paper)

Editor | Bai Cai Ye

Real-time, autonomous, iterative interaction of experiments and theory without human intervention?

The iterative cycle of theoretical prediction and experimental validation is fundamental to modern science.

However, in practice, the so-called “closed loop” in the experiment-theory cycle is often temporary and difficult to implement due to scale or time constraints.

Researchers at the University of Maryland proposed the Autonomous Materials Search Engine (AMASE), which explores materials through autonomous, continuous cycles of experimental and computational prediction-driven interactions.

They applied this formalized approach to rapidly map temperature-composition phase diagrams. The process of experimental determination of thin film phase boundaries is intertwined with real-time updates of phase diagrams using CALPHAD.

AMASE can accurately determine the eutectic phase diagram of the Sn-Bi thin film system with just one self-guided experiment, reducing the number of experiments by six times and only sampling a small part of the phase space.

This research was published under the title Real-time experiment-theory closed-loop interaction for autonomous materials science in Science Advances on July 2, 2025.

Research Background

Active learning-driven autonomous experiments use Bayesian Optimization (BO) to dynamically guide experiment sequences, accelerating scientific discovery. Automated platforms combined with active learning algorithms enable robot scientists to make autonomous decisions, especially effective in materials discovery such as quantum dots synthesis and solar cell optimization.

These autonomous systems greatly reduce the number of experimental iterations, efficiently map phase diagrams, and identify phase boundaries, advancing functional material development. However, there remains a natural gap between computational models and real experiments.

Efforts to bridge this gap include integrating computational models into autonomous workflows, comparing pre-prepared or existing computational data with experiments to guide subsequent iterations.

Within the BO framework, physical models are incorporated into probabilistic models like Gaussian Processes (GP), typically at the kernel, mean, input/output, or acquisition function levels.

As part of the autonomous closed-loop iteration, dynamically modifying physical priors or theories remains largely limited. Real-time chemical reactions, constrained by kinetics, pose significant challenges due to their urgency and time sensitivity.

AMASE

In recent research, Maryland University researchers introduced the Autonomous Materials Search Engine—AMASE. Driven by Bayesian active learning, it enables real-time, iterative interaction between experimental observations and computational modeling, continuously informing and adjusting each other during operation.

Specifically, the team applied this system to map the Sn-Bi thin film eutectic phase diagram. AMASE performs active learning for composition selection, XRD measurements and analysis, heat treatment, Gaussian Process classification for phase boundary determination, and thermodynamic calculations in a cyclic process.

By continuously updating Gibbs free energy calculations combined with Bayesian autonomous experiments, the researchers only sampled a small part of the composition-temperature phase space to obtain the full phase diagram.

Diagram: Overview of AMASE workflow for mapping Sn-Bi phase diagram. (Source: Paper)

In the lab, a real-time run to construct the Sn-Bi thin film phase diagram took only over 8 hours, reducing experiments by six times compared to detailed grid mapping over the same range. This is crucial for materials with volatile elements like Sn and Bi, which oxidize easily.

The authors noted: “Sn-Bi thin film system is a typical test case for AMASE workflow. Although the bulk phase diagram of Sn-Bi is well known, thin film phase diagrams differ. The low melting point of Sn-Bi makes phase transitions easy to achieve without extra hardware. Its tendency to oxidize underscores the need for accelerated AMASE experiments.”

Additional Extensions

Future work involves extending AMASE workflows to unknown phase systems, requiring advanced phase recognition methods and further CALPHAD implementation improvements.

While previous studies show the possibility of detecting unknown/new phases, comprehensive characterization from thin film XRD data is challenging. Machine learning-based phase recognition can actively monitor phase distributions, potentially replacing current peak detection and tracking workflows.

Moreover, materials databases like AFLOWlib and first-principles predictions can be linked or preloaded into AMASE to forecast potential new phases. Once identified, their Gibbs energy functions can be constructed and incorporated into the optimization process.

Bold Ideas

Researchers envision using large language models (LLMs) with context learning to achieve this. Establishing a model context protocol server could enable LLMs to interact directly with CALPHAD software for high-precision optimization.

Workflow diagram: Illustration of AMASE’s iterative interaction between real-time experiments and CALPHAD modeling. (Source: Paper)

In hardware, high-temperature XRD combined with environmental control and scanning stages can study high-melting-point elements (>1000°C). Modular batch sample holders will facilitate research on high-temperature systems.

Some autonomous workflows for similar purposes, like materials optimization, already exist, but AMASE is unique in integrating computational and experimental tasks in real-time operation.

The main feature of this multi-cycle workflow is that the updated CALPHAD calculations (every 40 minutes) guide the internal phase boundary search loop.

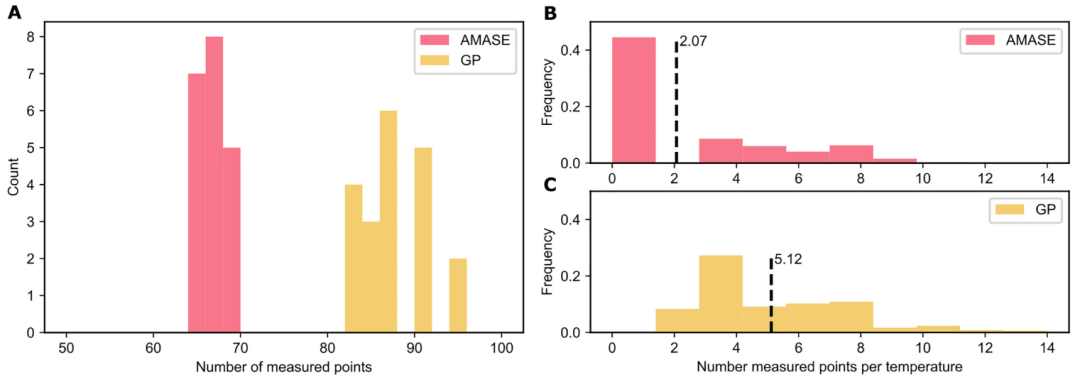

To further demonstrate the interaction between physical models and experimental phase boundary measurements, researchers developed a separate workflow where phase boundary tracking is fully managed by a baseline GP method. Key statistical metrics compare this method with AMASE’s performance.

Comparison of AMASE and GP workflows in two statistical parameters. (Source: Paper)

Both methods used 20 simulations based on phase diagrams generated during real-time operation. The GP method explicitly searched for dissolution lines and liquidus lines. Results show that AMASE requires significantly fewer measurements, thanks to CALPHAD’s extrapolation capabilities.

Compared to AMASE, GP exhibits higher variance, with broader measurement distributions and larger tails at each temperature point, as shown in the figures.

In Figure B, the high frequency at bin 0 is due to AMASE’s ability to “skip” many temperature points, leveraging CALPHAD’s basic extrapolation, which is impossible with GP.

Conclusion

Scientists demonstrated a materials exploration method where experimental and computational tasks autonomously cycle and influence each other. Using the AMASE workflow, they rapidly mapped the Bi-Sn thin film phase diagram and validated the predicted eutectic temperature through subsequent experiments.

This approach allows exploration of multi-dimensional parameter spaces beyond traditional physical conditions. Future extensions include integrating other computational methods like density functional theory and convex hull analysis, and coupling thread-based experimental-theoretical cycles in other research fields.

This study shows that autonomous materials discovery systems can be built using relatively inexpensive laboratory tools, demonstrating the practicality and impact of autonomous science for the public.

Paper link: https://www.science.org/doi/10.1126/sciadv.adu7426